Steel casting is a versatile and specialized form of casting that involves the use of different types of steel to create strong and durable products. It is widely used in various industries due to its superior strength, durability, and high resistance to shock and wear. In this blog, we will explore the different aspects of steel casting, its benefits, and its applications.

Overview of Steel Casting

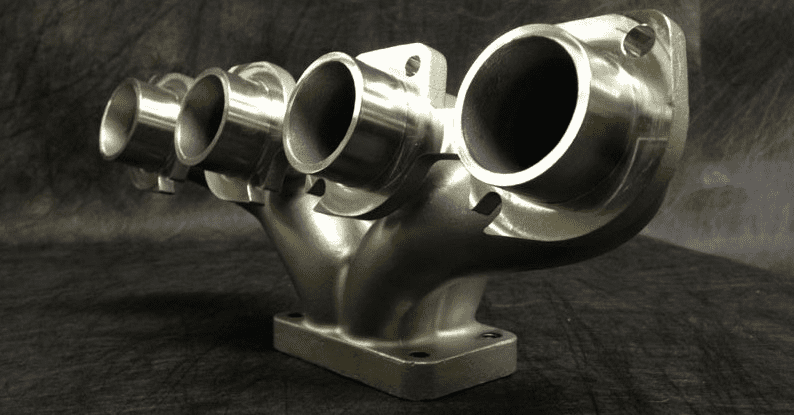

The process of steel casting involves melting and pouring steel into a mold to create a desired shape or product. The melted steel is poured into the mold and left to cool and solidify. The casting process may also involve other techniques such as sand casting, investment casting, or shell molding to create complex shapes and designs.

Steel casting is used for applications that require high strength and durability. It has a tensile strength of over 70,000 psi and can withstand heavy loads and high temperatures. Steel casting offers excellent wear resistance, corrosion resistance, and hardness, making it an ideal material for heavy-duty applications.

Benefits of Steel Casting

Steel casting offers several benefits over other casting materials. Some of the major benefits are:

1. High Strength: Steel casting provides high strength and durability, making it ideal for applications that require reliable and long-lasting products.

2. Wear Resistance: Steel casting has excellent wear resistance, making it ideal for applications that involve high wear and tear.

3. Corrosion Resistance: Steel casting offers excellent corrosion resistance, making it ideal for applications that require resistance to harsh environments.

4. Machinability: Steel casting is easy to machine and can be easily shaped, drilled, and tapped to create complex shapes and designs.

Applications of Steel Casting

Steel casting is used in various industries, including automotive, aerospace, construction, power generation, and mining. Some of the common applications of steel casting are:

1. Automotive: Steel casting is used in the automotive industry for engine parts, transmission parts, and other components that require high strength and durability.

2. Aerospace: Steel casting is used in the aerospace industry for engine parts, landing gears, and other components that require high strength and corrosion resistance.

3. Construction: Steel casting is used in the construction industry for structural components, bridges, and other applications that require high strength and durability.

4. Power Generation: Steel casting is used in the power generation industry for turbine components, generator components, and other applications that require high strength and corrosion resistance.

Conclusion

Steel casting is a versatile and specialized form of casting that provides high strength, durability, and wear resistance. It is used in various industries for applications that require reliable and long-lasting products. Steel casting offers several benefits over other casting materials and is ideal for heavy-duty applications. If you require strong and durable products, steel casting may be the right choice for you.